Other products

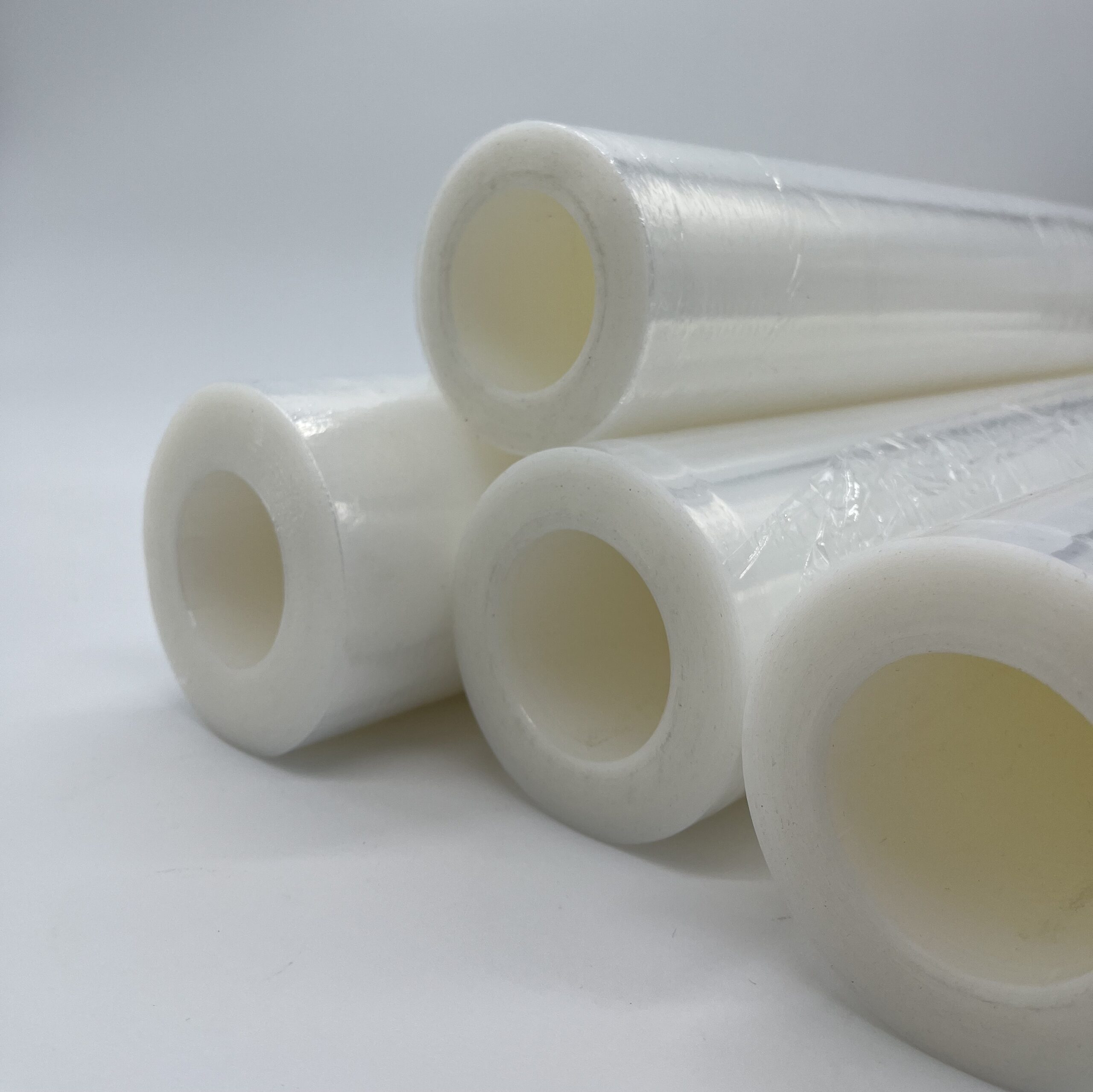

Fully automatic machine for the production of coreless stretch film.

Thanks to innovative technology and high speed of rewinding, the machine ensures high efficiency.

The machine is capable of producing coreless manual and machine rolls.

It is possible to equip the machine with the traditional film rewinding function with the use of cores (2in1).

Simple and intelligent solutions ensure trouble-free cooperation between the machine and the operator.

The technology of production of coreless film reduces the amount of waste generated in the production process, thus eliminating the problem of disposal of cardboard cores after using the film. Film and film waste can be recycled, making the film more environmentally friendly and reducing costs throughout the supply chain.

The unit weight of a pallet can be reduced by up to 20% thanks to the elimination of cardboard cores.

The implementation of the RCLS 500 tube-free film rewinder is one of the greatest achievements of ENGINEERING CC.

Individual

configuration

Innovative

technology

Friendly

service

Film thickness:

6 - 30 microns

Max Jumbo Roll Diameter:

460 mm

Jumbo Roll Bushing Diameter:

76 mm

Jumbo film web width:

300 – 550 mm

Jumbo Roll Centering:

Manual

Jumbo roll loading:

electric elevator

Max Jumbo Roll Weight:

70 kg

Maximum diameter of the wound reel:

250 mm

Winding Roll Inner Diameter:

50/76 mm

Required air pressure in the system:

7 - 8 bar

Air consumption:

180 l / min

Power supply:

3 phase, 400V, 50Hz

Electricity consumption:

9 kW

Machine linear speed:

1100 m / min

Settings set by the touch panel

Possibility to rewind CAST and BLOW films