Other products

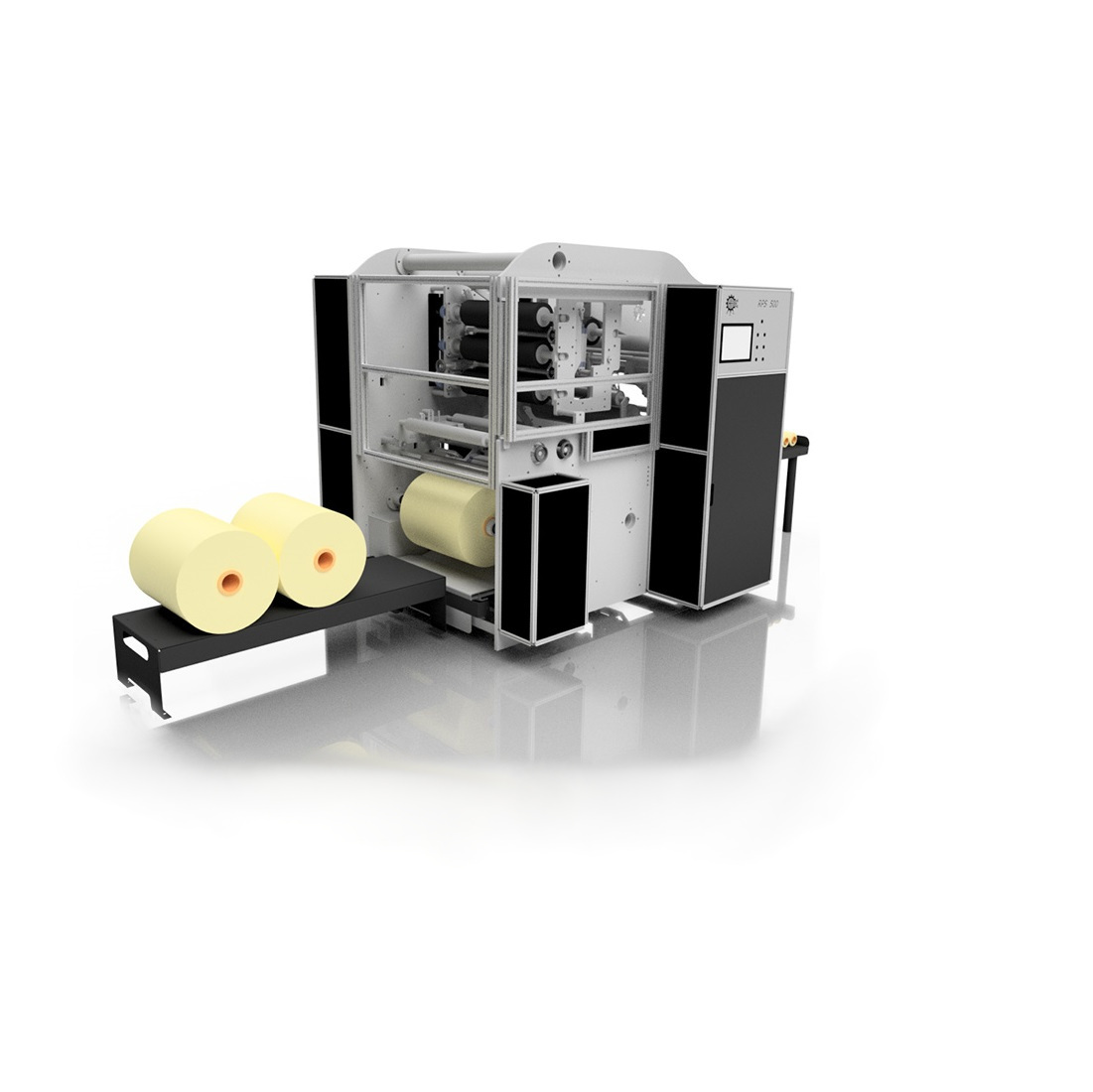

Fully automatic machine for the production of PRE STRETCH film, pre-stretched film. As the only company in Poland, we have developed a technology for the production of pre-stretch film for very thin cardboard cores. This has very high economic benefits, due to the possibility of using thin and light cores for the production of films.

The rewinder is equipped with a four-stage film stretching system, designed by our company ENGINEERING CC.

The RPS 500 rewinder can also produce conventional stretch film, without using the pre-stretch function, it can be used as a traditional stretch film rewinder, function (2in1).

The machine can produce film in manual and machine reels.

The RPS 500 is equipped with a double edges system and an oscillating roll winding system.

Pre Stretch film is a stretch film with a low thickness ranging from 5 to 12 microns.

The film has better performance parameters than standard stretch films.

Switching from standard film to pre-stretch film has many advantages:

● EFFICIENCY – the pre-stretch film in the same volume as the standard film has a length 3 times longer.

● EASE OF USE – does not require strong tension when wrapping pallets.

● ECOLOGY – The film is environmentally friendly, it generates about 50% less waste during packaging.

Rewinding performance depends on:

● Thickness of the input film,

● Degree of stretch,

● Quality of the input film.

.

POSSIBILITY OF MACHINE CUSTOMIZATION ON REQUEST BY INDIVIDUAL CONFIGURATION

Individual

configuration

Innovative

technology

Friendly

service

The system of pre-stretching of the film in the range of 0-400%, regulated by PLC

Permanent monitoring of the tension of the film web wound via PLC

Input film thickness range:

8 - 30 microns

Maximum Jumbo Roll Diameter:

460 mm

Jumbo Roll Bushing Diameter:

76 mm

Jumbo film web width:

300 – 550 mm

Jumbo Roll Centering:

Manual

Jumbo roll loading:

electric elevator

Max Jumbo Roll Weight:

70 kg

Maximum diameter of the wound reel:

250 mm

Winding Roll Inner Diameter:

38, 50, 76 mm

Required air pressure in the system:

7 – 8 bar

Air consumption:

180 l/min

Power supply:

3 fazy, 400 V, 50 Hz

Electricity consumption:

12 kW

Maximum linear speed of the machine:

1100 m/min

Settings are made via the touch panel

Possibility to rewind CAST and BLOW films